- Up to 25% off

Ocean Safety

Revere Standard Life Raft, 4 - 6 Person

Sale price From $1,575.00 Regular price $2,100.00Unit price /UnavailableIn stock (55 units) - Up to 19% off

Superior Life-Saving Equipment

Superior Offshore Stream Life Raft, 4 - 8 person

Sale price From $1,679.00 Regular price $1,995.00Unit price /Unavailable - Up to 28% off

Superior Life-Saving Equipment

Superior HALO Compact Life Raft, 2-8 Person

Sale price From $1,150.00 Regular price $1,549.00Unit price /UnavailableIn stock (29 units) - Up to 21% off

Revere

Revere Coastal Compact Life Raft, 2-6 Person, Valise Bag

Sale price From $1,250.00 Regular price $1,535.00Unit price /UnavailableIn stock (36 units) - Up to 13% off

Superior Life-Saving Equipment

Superior Coastal Surge Life Raft - 6 Person

Regular price From $1,739.00Unit price /UnavailableIn stock (49 units) - 19% off

Lalizas

LALIZAS Leisure Life Raft, 6 Person

Sale price $1,295.00 Regular price $1,600.00Unit price /UnavailableBackordered - 25% off

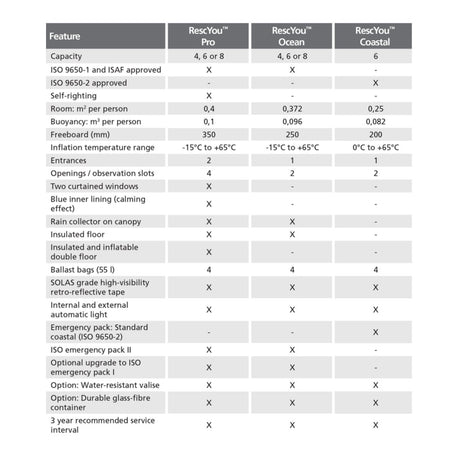

VIKING

VIKING RescYou PRO 4 Person in a Valise

Sale price $3,000.00 Regular price $4,010.00Unit price /Unavailable - Up to 13% off

Revere

Revere Offshore Commander 4.0 Life Raft, 4-8 person

Sale price From $1,999.95 Regular price $2,299.00Unit price /UnavailableIn stock (80 units) - Up to 9% off

Superior Life-Saving Equipment

Superior HALO + Compact With Canopy Recreational Life Raft, 2-8 person

Sale price From $1,395.00 Regular price $1,540.00Unit price /UnavailableIn stock (40 units) - Up to 15% off

Superior Life-Saving Equipment

Superior ISO Wave Racer Life Raft, 4 - 12 Person

Sale price From $2,099.00 Regular price $2,305.00Unit price /Unavailable - Up to 17% off

Superior Life-Saving Equipment

Superior ISO Wave Breaker Self-Righting Life Raft, 4-12 Person

Sale price From $2,595.00 Regular price $2,950.00Unit price /Unavailable - Up to 17% off

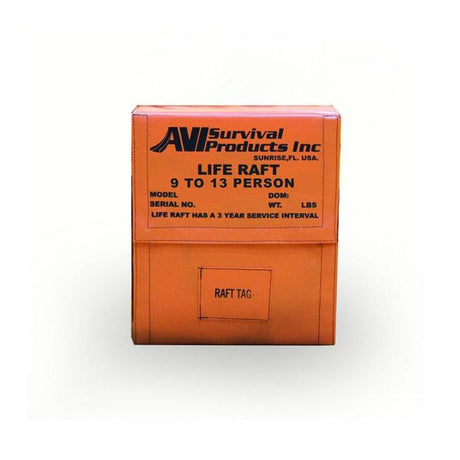

AVI Survival Products

AVI Survival Aviation Life Raft 9 Person - NON TSO

Sale price From $3,237.65 Regular price $3,727.50Unit price /Unavailable - Up to 13% off

Revere

Revere Aero Compact Aviation Life Raft, 2-4 Person, Valise Bag

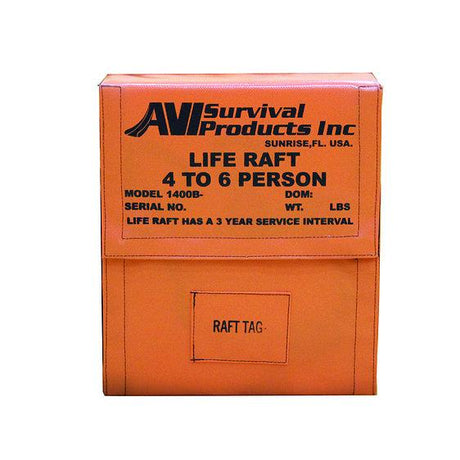

Sale price From $1,450.00 Regular price $1,590.00Unit price /Unavailable AVI Survival Products

AVI Survival Aviation Life Raft 4 Person - NON TSO

Regular price From $2,830.00Unit price /UnavailableSuperior Life-Saving Equipment

Superior Life-Saving Life Raft Cradle and Hydrostatic Release Unit

Regular price From $600.00Unit price /Unavailable